Spline couplings are essential components used to transmit torque between rotating shafts in gas-turbine aeroengines. This includes accessory drive trains and accessory gear box components such as fuel pumps. They permit component assembly and disassembly during engine building and maintenance.

During aeroengine operations, spline couplings experience angular misalignments coupled with high torque and rotational speeds as high as 15000 rpm. These loading conditions cause fretting wear in the spline couplings which can cause reduced functionality of the components and may lead to premature component failure.

The Gas Turbine Transmissions Systems UTC has developed a predictive model to help design against fretting wear in spline couplings. Experiments to capture the conditions spline couplings undergo during a typical flight, especially misalignments and high rotational speeds, are required to validate this model’s capabilities in predicting fretting wear.

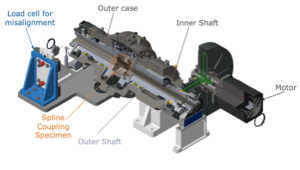

Angularly Misaligned Spline Coupling Test Rig

This work package focusses on developing a test rig which can be used to undertake experiments to validate the predictive model. This test rig also incorporates flexibility for considering wider engineering problems.

Some key capabilities include:

- misalignment: 0.75°

- applied torque: 500 Nm

- speed: 15,000 rpm

Key features include:

- A self-contained and temperature controlled oil system for bearing lubrication.

- A supervisory control and data acquisition system to monitor the rig and oil system health. The system monitors vibrations, bearing temperature, oil feed temperature, and comprises of rig operating safety features.

- All measurement signals are recorded at 100 Hz, with the shaft torque and bending moment signals processed at 6 kHz.

Coming Soon